-

CNC Precision Machining

-

Stainless Steel CNC Machining Services

-

Magnesium Precision Machining

-

Titanium CNC Machining

-

Low Volume CNC Machining

-

Sheet Metal Fabrication Service

-

CNC Milling Service

-

5 Axis CNC Machining Services

-

Plastic Injection Molding Service

-

CNC Turning Service

-

Die Casting Service

-

Vacuum Casting Rapid Prototyping

-

Custom 3D Printing Services

-

David WyameI worked with JYH for many years and They help me doing some high precision metal parts,it is really good and high tolerance.

David WyameI worked with JYH for many years and They help me doing some high precision metal parts,it is really good and high tolerance. -

Brian“JYH not only committed to manufacturing all of our parts with only minor adjustments but also offered competitive costs that fit within our budget, all while ensuring strict adherence to our tight timelines. “ DOM BU

Brian“JYH not only committed to manufacturing all of our parts with only minor adjustments but also offered competitive costs that fit within our budget, all while ensuring strict adherence to our tight timelines. “ DOM BU -

Rabiul“JYH fully meets our demands and construction requirements. Its staff has the skills to understand and satisfy the demand for very complex designs to micro-machining. In addition, the delivery time is very fast. This is very important to us as we make “Build on order” devices.” – OPEN

Rabiul“JYH fully meets our demands and construction requirements. Its staff has the skills to understand and satisfy the demand for very complex designs to micro-machining. In addition, the delivery time is very fast. This is very important to us as we make “Build on order” devices.” – OPEN

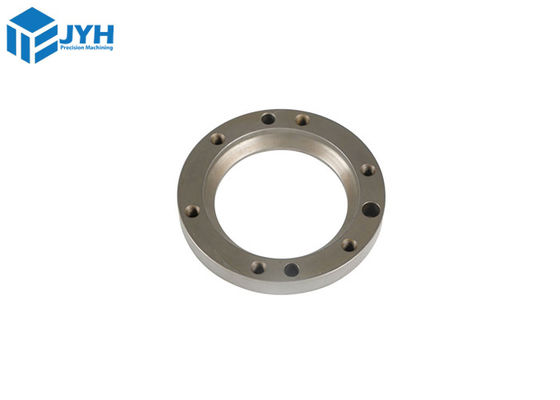

Anodized 5 Axis CNC Machining Services OEM / ODM Parts ISO9001

| Place of Origin | China |

|---|---|

| Brand Name | JYH Technology |

| Certification | ISO9001 Certificate of quality system/16949 |

| Model Number | metal prototype |

| Minimum Order Quantity | 1 Piece |

| Price | USD 10-200 pieces |

| Packaging Details | For small parcels less than 25KG, we generally adopt paper cartons; For goods over 25KG, we will use custom wooden cases. |

| Delivery Time | 2-5 works day |

| Payment Terms | T/T/Paypal, Western Union |

| Supply Ability | 1000 pieces one week |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | 5 Axis CNC Machining Services | Express Way | DHL/FEDEX/UPS |

|---|---|---|---|

| Lead Time | 5-10 Working Days | Material | AL 6061 Serie/Stainless Steel/Magnesium Alloy/Titanium Alloy/Copper |

| Process Way | CNC 5 Axis Machining/Lathe/milling/Turning | Tolerance | +/-0.001 Mm To +/-0.005mm |

| Surface Finish | Anodized/Electroplating/Passivation/Blackening And So On | ||

| High Light | 5 Axis CNC Machining Services ISO9001,Anodized 5 Axis CNC Machining Services,OEM 5 Axis CNC Machining Services |

||

Custom Five Axis CNC Machining Metal Enclosure Services With Precise Tolerance

Our ISO 9001 certification shows that we fabricate 5-axis milled parts to meet the tightest tolerance requirements.

Our standard tolerance for CNC-milled plastics is ISO-2768-m and ISO-2768-f for metals.

Get high-quality and precise complex parts with top-notch dimensional stability.

5-axis machining services offer unparallel speed and flexibility.

Parts Certifications

ISO 9001:215 | AS9100D | ITAR Registered

►Free & Automatic DFM feedback

►Tolerances down to ±0.0004″ (0.01mm)

►24/7 engineering support

![]()

5 Axis CNC Machining Facilities

JYH implements strict quality control protocols to ensure that every client receives superior-quality products.

We have dedicated workshops with state-of-the-art equipment for a wide range of operations.

This way, we incorporate meticulous inspection in our 5-axis CNC machining processes.

![]()

|

Simultaneous 5 Axis CNC Machining

|

3+2 Axis CNC Machining |

| ♦Fast, effective, and continuous 5-axis CNC machining with improved transitioning and surface quality. Here, we use 5-axis machining center that can continuously adjust the movements on all five axes without stopping. Our 5-axis CNC machining has intelligent functionalities to ensure efficient continuous processes and transitions. | ♦Take advantage of the optimal 3+2 axis machining technology for your applications. The process keeps the part fixed in a specific orientation to allow the usual 3-axis machining process. Our 3+2 axis machining uses shorter, more rigid cutting tools to offer the parts better dimensional stability. Get complex CNC machined parts with tight tolerances at lower costs and cycle time. |

![]()

Product Specifications:

Our 5-axis CNC machining service can handle a variety of materials, including metals, plastics, and

composites. We can produce parts with tolerance +/- 0.001, ensuring tight tolerances and surface finishes

as per your requirements.

| Business Type | Factory / Manufacturer | Tolerance | +/-0.01mm ~ +/-0.05mm |

| Service | CNC Machining,Turning and Milling,CNC Turning,OEM /ODM Parts | ||

| Material |

1). Aluminum: AL 6061-T6, 6063, 7075-T etc. 2). Stainless steel: 303,304,316L, 17-4(SUS630) etc. 3). Steel: 4140, Q235, Q345B,20#,45# etc. 4). Titanium: TA1,TA2/GR2, TA4/GR5, TC4, TC18 etc. 5). Brass: C36000 (HPb62), C37700 (HPb59), C26800 (H68), C22000(H90) etc. 6). Copper, bronze, Magnesium alloy, Delran, POM,Acrylic, PC, etc.

|

||

| Finish |

●Sandblasting, Anodize color, Blackening, Zinc/Nickel Plating, Polish. ●Power coating, Passivation PVD, Titanium Plating, Electro galvanizing. ●electroplating chromium, electroscopes, QPQ(Quench-Polish-Quench). ●Electro Polishing, Chrome Plating, Knurl, Laser etch Logo, etc. |

||

| Main Equipment | CNC Machining center(Milling), CNC Lathe, Grinding machine, | ||

| Cylindrical grinder machine, Drilling machine, Laser Cutting Machine,etc. | |||

| Drawing format | STEP, STP,IGS, etc. or samples. | Surface roughness | Ra 0.1~3.2 |

| Inspection | Complete inspection lab with Micrometer, Optical Comparator, Caliper Vernier,CMM | ||

| Depth Caliper Venire, Universal Protractor, Clock Gauge, Internal Centigrade Gauge | |||

| Capacity | CNC turning work range: φ0.5mm-φ150mm*300mm | ||

|

CNC milling work range: 510mm*1020mm*500mm |

|||

Tolerance for 5 Axis CNC Machining Services

| Type |

Tolerance |

| Linear dimension |

+/- 0.015 mm +/- 0.002 inch |

| Hole diameters (not reamed) | +/- 0.015 mm +/- 0.002 inch |

| Shaft diameters | +/- 0.015 mm +/- 0.002 inch |

| Part size's limit | 860 * 660 *650 mm 39.0 * 23.5 * 23.5 inch |

CNC 5 Axis CNC Machining Capabilities:

| Item |

Factory Capabilities

|

Network Capabilities |

| Maximum Part Size | 22 in. x 14 in. x 3.75 in. (559mm x 356mm x 95.3mm) | 25.5 in. x 25.5 in. x 11.8 in. (650mm x 650mm x 300mm) |

| Minimum Part Size | 0.25 in. x 0.25 in (6.35mm x 6.35mm) | 0.019 in. (0.50mm) |

| Tolerances | +/- 0.005 in. (+/- 0.13mm) | +/-0.001 in. (0.020mm) |

| Radious | Sharp inside corners on a part will be radius (rounded) as a natural result of the CNC machining process. | |

| Text |

Plastic and soft metals:

Minimum width of 0.018 in. (0.457mm), depth of 0.0118 in. (0.3mm). Example text size would be 16 point Arial Rounded MT font.

Hard metals:

Minimum width of 0.033 in. (0.838mm) and depth of 0.0118 in. (0.3mm). Example text size would be 22 point Arial Rounded MT font.

Hard metals:

Minimum width of 0.033 in. (0.838mm) and depth of 0.0118 in. (0.3mm). Example text size would be 22 point Arial Rounded MT font.

|

|

Features Of 5 axis CNC Machining Services :

5 Axis CNC machining services at JYH Precision Machining have many advantages for product development that

can make it the ideal solution not only for rapid prototyping but also for volume production.

Here is what you should consider.

- Quick removal of large amounts of metal as well as engineering-grade plastic resins.

- Highly accurate and repeatable.

- Excellent for making complex geometries.

- Versatile.

- Suitable for many different kinds of substrates.

- Scale-able volumes from one to 100,000.

- Low investment in tooling and preparation cost.

- Fast turnaround.

- Parts are full-strength and can be put into service immediately.

- Excellent surface finishes.

- Easily customized.

Surface Finish Options for 5 Axis CNC Machining Parts

Our part finishing services are exceptional as our teams are experts in plastic, composite, and

metal surface finishing.Furthermore, we have state-of-the-art machines and infrastructure to bring your idea to life.

![]()

Applications of 5 Axis Milling

Our 5-axis milling services is your best bet when it comes to manufacturing complex, highly precise components

for a wide range of industries. Our manufacturing capabilities allow us to accelerate the production of several components,

including:

►Automotive components: Engine housing, light guides, valves, engine covers, inspection jigs;

►Aerospace parts: Fuselage sections, bulkheads, landing gear components

Medical and Surgical tools: Forceps, scalpels, spacers, clamps, cutters, surgical scissors;

►Military components: Submarine parts, turbine blades, engine parts, weapons, sensors;

Military components: Submarine parts, turbine blades, engine parts, weapons, sensors.

Quality Inspection

- In addition to our stringent in-process controls, all components must pass a thorough final inspection.

we have a coordinate measuring machine, salt spray testing machines, profile projectors and other precision

measuring devices, etc.

- Customers' CAD drawings can be directly imported in the coordinate measuring machines (CMM) for a

direct comparison to the dimensions that are taken from the physical part.

- All testing is conducted in a 20 degree Celsius climate-controlled inspection room and the CMM is calibrated to

GB/T 16857.2-2006 (ISO10360-2:2001) standards. All components and sub-assemblies are 100% inspected,

identified with a logo if required and a final inspection is generated pertaining to all the critical dimensions.

![]()

Our payment method

![]()

Our shipping method

![]()

Frequently Asked Questions

► When should I choose 5-axis CNC machining?

The flexibility of 5-axis CNC machining allows the creation of complex components with complex shapes and geometrical details.

The stability of the machining tool also gives more consistent and smoother surface finishes.

Therefore, you should choose 5-axis machining whenever you need to produce complex parts with tight tolerances.

► What’s the maximum part size for 5-axis CNC machining?

Our 5-axis milling machines can accommodate a length of 42 inches bar stock.

This allows us to work on a wide range of projects for various applications.

► How much does your CNC machining service cost?

The cost of your CNC machining projects is not fixed as it depends on the characteristics of your project

such as the design, and tolerances. Machining times of the material to be used in the project also contribute to this pricing.

For example, if you’re making a part that has a combined machining and material cost of $2 and a setup cost of $200,

one part will cost $202. However, if you make 200 parts, each would cost $3!

Our workshop

![]()

Try JYH technology Now!All information are secure and confidential by us!