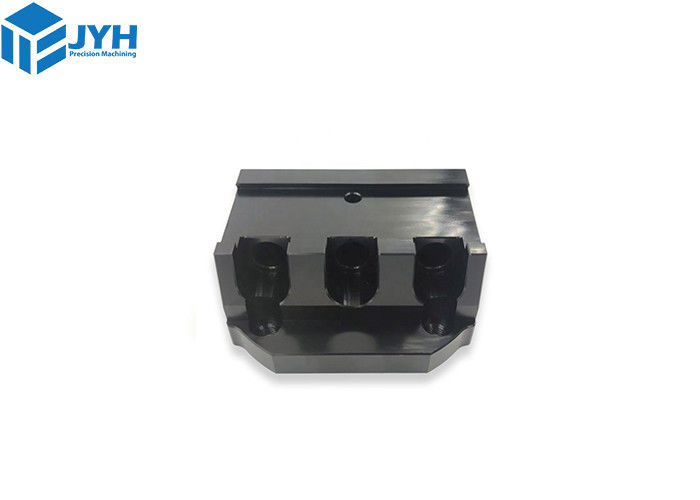

Low-Volume CNC Machining Aluminum Alloy Turned Components

Why use CNC machining to manufacture small batches of aluminum parts?

At JYH, we offer the best small batch CNC machining for aluminum parts. We live and develop on the slogan of low cost, high quality and

fast delivery. More and more industries choose CNC machining small batch aluminum parts. Aluminum is an awesome material because

of its amazing properties. In terms of processing materials, it is cheaper due to the lower processing time. The small aluminum parts are

also strong and resistant to rust or corrosion.

In addition, aluminum machined parts have excellent electrical conductivity and ductility. Today, small batch CNC machining of aluminum

parts has a range of uses. These include the automotive, medical, military and aerospace industries. These parts require precision

machining specialists to manufacture.

Quality Reporting

All parts are inspected for cosmetic conformance to workmanship standards and dimensional conformance on at least three dimensions

(typically X, Y, and Z), but with production parts for machining, we also provide conventional inspection reporting like FAIs, Certificate of Compliance (CofC) documentation, and additional like ISO 9001 quality certificated and AS9100 and ISO9001.

What grade of aluminum do we use in JYH?

|

Aluminum 6061

|

This is the most preferred aluminum grade. This is since it avails the following key features. One it offers great mechanical properties that allow us to weld it easily. In addition, it offers good toughness that makes it awesome or extrusion. We can easily anodize it and its corrosion resistance makes it ideal for harsh environs. |

|

Aluminum 7075

|

This is the second most preferred aluminum grade after the previous one. It is renowned for its fatigue strength. We can thus use it as a low volume part for tough components. Examples are fuselages and aircraft wings. Others include bike parts and rock climbing gear. In addition, it is lightweight which gives it more appeal. We can also use it as a reflector for cars as it has amazing polish features. |

|

Aluminum 5052

|

We usually use this aluminum grade in sheet metal processing. We can also opt for it when CNC machining low-volume parts that are likely to face a salty environment. This is since it confers the right amount of corrosion resistance. Examples of clients are those from the marine and industrial set up. In addition, we can easily punch, bend, and shear the sheets we make using it. |

|

Aluminum 6063

|

This aluminum grade offers amazing mechanical features. It thus allows us to easily weld it and apply heat treatment. We may use it when creating complex shapes that have smooth surfaces. There are thus several low volume aluminum parts we can machine using it. These namely sign frames, roofs, doorframes, and window frames. |

1.Advantages of aluminum

1) Excellent mechanical properties

Aluminium is one of the most commonly used machining materials due to its excellent mechanical properties. Some of these features include softness, affordability, durability and its ability to resist corrosion. Precision machined CNC aluminum parts have become commonplace in recent years, especially in military, medical, aerospace and industrial engineering.

2) General materials

The advantage of aluminum is that it is a universal material that can be used in various fields. It has great features such as being light and durable. Aluminum also needs absolute brilliance, so aluminum can be used in different fields such as aircraft manufacturing, power generation and automobile manufacturing. In the automotive production industry, it can be used to make reflectors commonly used in automotive lamps.

Why choose Low Volume CNC Production:

1. Reduced Piece-For Higher Quantities

Lower your part cost when you order higher volumes of production parts.

2. Inspection Reporting and Certifications

Get added quality assurance from conventional FAI reporting, COC documentation, and ISO9100 certification.

3. More Finishing Options

Choose from anodizing and chromate plating for complete parts from one supplier.

4. Supply Chain Flexibility

Avoid warehousing fees by ordering only the amount (starting at quantity 10) you need each month.

The benefits of CNC machining aluminum parts

|

Easy to bend

One of the benefits of using CNC machining processes to machine alumium CNC part is that they can be easily bent. Unlike steel, the aluminum material can be easily rotated during processing because of the thickness of the aluminum that can take advantage of various forming methods. Best results are achieved by stamping and machining to easily obtain various shapes of aluminum CNC parts.

|

Easy to process

Another benefit of the aluminum CNC machining process is that the material can be easily fabricated by punching, folding and drilling. You can use it to form various shapes of parts as needed. Compared to steel, the energy used in aluminum processing is much lower.

|

|

Low temperature resistance

Aluminum material is low temperature resistant. We all know how delicate steel can be, especially in welding areas or low temperature environments. Compared to steel, aluminum can be easily machined at low temperatures.

|

Customized post-processing

Aluminum can be customized according to customer’s requirements. There are a few things you can do to give it the perfect custom look.Aluminum alloy CNC parts can be plated in various colors according to your requirements. Some colors you can try include black, blue and green.

|

We offer more competitive pricing at higher quantities in addition to tighter tolerances, hardware assembly, first article inspection (FAI) reporting, material certifications, and additional finishing options like anodizing and chromate plating. It’s CNC machining designed around your project needs—whether prototyping or production.

CNC Machining Method of Aluminum Parts

- Milling: A rotating milling cutter is moved over the aluminum piece, removing excess material to obtain the desired shape and size. Commonly used milling methods include end milling, face milling, and extrusion milling.

- Drilling: Use a drill bit to drill holes in aluminum parts; often used to process bolt holes, threaded holes, etc.

- Boring: Boring is a method of reprocessing drilled holes. Boring tools are used to finely machine holes to meet design requirements.

- Tapping: Cut threads into holes in aluminum parts for subsequent threaded connections with other parts.

To ensure quality, we send a CMM test report to our customers, which ensures that you receive your small batch of high quality CNC machined parts.

In small batch CNC machining assembly, tolerances and dimensions can fully meet your requirements.

Our workshop

Product quality assurance:

Low volume From Prototyping to Production

JYH custom sheet low volume services are highly versatile and applicable to a wide range of industries and purposes.

JYH custom low volume services can be used for various applications such as mold tooling, rapid prototyping, and

custom manufacturing, and more.

Functional Prototypes

Functional prototypes can be built using various materials and manufacturing methods, depending on the

complexity and purpose of the product.it is a critical step in the product development process,

helping to reduce risks, refine designs, and ensure that the final product meets user expectations.

Prototyping

Prototyping refers to a set of techniques and processes used to quickly create prototypes of a product.

It is used for testing, evaluation, and iteration during the product development cycle.

Prototyping plays a crucial role in modern product development by enabling innovation, reducing time-to-market,

and enhancing the quality level and functionality of products.

On-Demand Production

On-demand production offers swift and flexible manufacturing tailored to specific needs. It enables efficient production of parts as required, minimizing inventory and lead times.

Shipping way:

Payment method:

After sales service:

FAQ

- Are you a trade company or manufacturer?

We are a manufacturer with more than 15 years of experience in CNC machining and

Low Volume CNC Machining Supplier Of Machined Prototype And Short-Run Production.

- Can you protective my business, will my drawing be safe after you get it?

Yes, we can sign the NDA before you send the drawing.

- Do you provide first article of inspection (FAI) service?

Yes, We offer FAIs on machined and molded parts.

- How soon can I get your quotation?

Within 1 hours or less and in nearly all cases.

- Available for customized design drawings?

Yes, CAD, STP, IGS, PDF, Solidwork, etc.

Product's packing way

Try JYH technology Now!All information are secure and confidential by us.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!