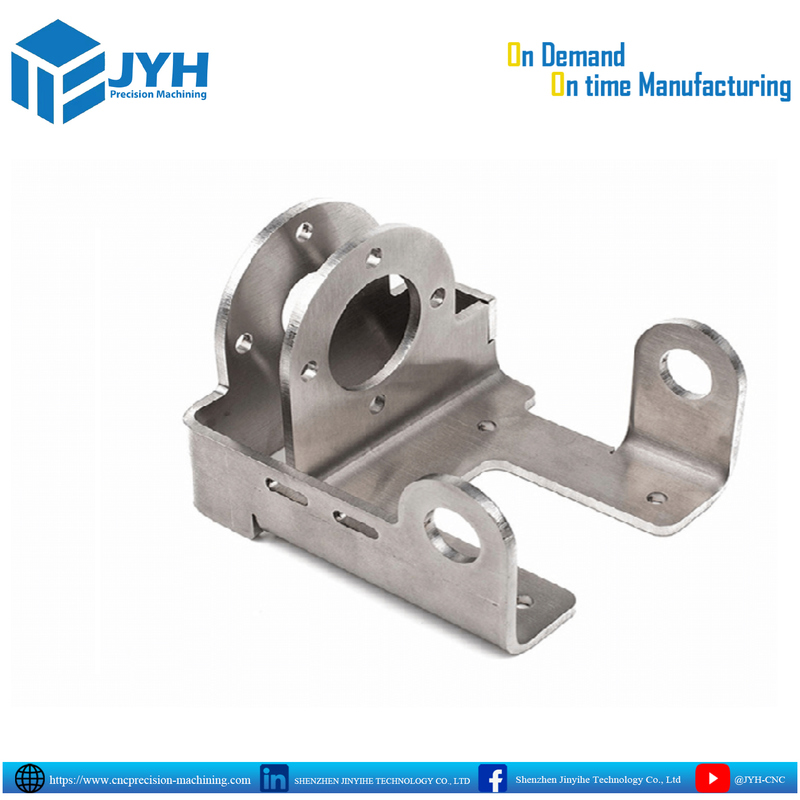

At JYH Precision Machining, we specialize in high-quality custom sheet metal fabrication to meet the demands of a wide range of industries. Our advanced CNC machining and precision sheet metal forming processes ensure accuracy, durability, and perfect surface finishes for every part we produce.

Whether you need simple brackets or complex enclosures, we deliver on-demand, on-time manufacturing with full support from design to final finishing.

Product Overview

Our custom sheet metal parts are made using CNC laser cutting, bending, stamping, and welding technologies. Each component is produced to exact customer specifications and is suitable for electronic housings, brackets, chassis, covers, enclosures, and mounting components.

We work with a variety of materials including stainless steel, aluminum, cold rolled steel, and galvanized steel, offering multiple surface finishing options such as powder coating, anodizing, zinc plating, and brushing.

Product Specifications

|

Specification

|

Details

|

|

Material Options

|

Aluminum, Stainless Steel, Cold Rolled Steel, Galvanized Steel, Brass

|

|

Thickness Range

|

0.5 mm – 10 mm

|

|

Manufacturing Process

|

CNC Laser Cutting, Bending, Stamping, Welding, Surface Treatment

|

|

Surface Finish

|

Anodizing, Powder Coating, Brushing, Zinc/Nickel Plating, Sandblasting

|

|

Tolerance

|

±0.05 mm

|

|

Production Capability

|

Low-volume prototyping to mass production

|

|

Applications

|

Enclosures, Brackets, Electronic Casings, Mounting Frames, Industrial Covers

|

|

Lead Time

|

7 – 15 Working Days (depends on quantity and complexity)

|

|

Quality Control

|

100% Inspection before shipment, ISO 9001 Certified

|

Key Features

· Precision Fabrication: High accuracy bending and cutting ensure perfect fit and assembly.

· Durable Materials: Corrosion-resistant and long-lasting metal options.

· Custom Finishing: Aesthetic and functional coatings available upon request.

· Fast Turnaround: From prototype to production — delivered on time, every time.

· Engineering Support: DFM (Design for Manufacturability) review before production.

Applications

Our sheet metal parts are widely used in:

· Medical Equipment Enclosures

· Industrial Machinery Components

· Automotive Brackets & Mounts

· Consumer Electronics Housings

· Aerospace & Communication Devices

Surface Finishing Options

|

Finish Type

|

Description

|

|

Powder Coating

|

Provides a durable and aesthetic finish with color options.

|

|

Anodizing

|

Enhances corrosion resistance and surface hardness (for aluminum parts).

|

|

Brushing

|

Smooth satin finish for a clean, modern look.

|

|

Zinc Plating

|

Prevents corrosion and enhances surface durability.

|

|

Sandblasting

|

Creates a uniform matte texture ideal for coatings or painting.

|

Why Choose JYH Precision Machining

✅ Fast Quotation & DFM Review

✅ Advanced CNC and Sheet Metal Equipment

✅ Strict Quality Control with Full Inspection

✅ Flexible Order Quantities (Prototype to Mass Production)

✅ Reliable Worldwide Shipping

Get a Custom Quote Today

Send us your 3D/2D drawings (STEP, STP, or PDF), and our engineering team will provide a free quotation and manufacturability feedback within 24 hours.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!