Engineered for Aerospace, Robotics, and High-Performance Systems

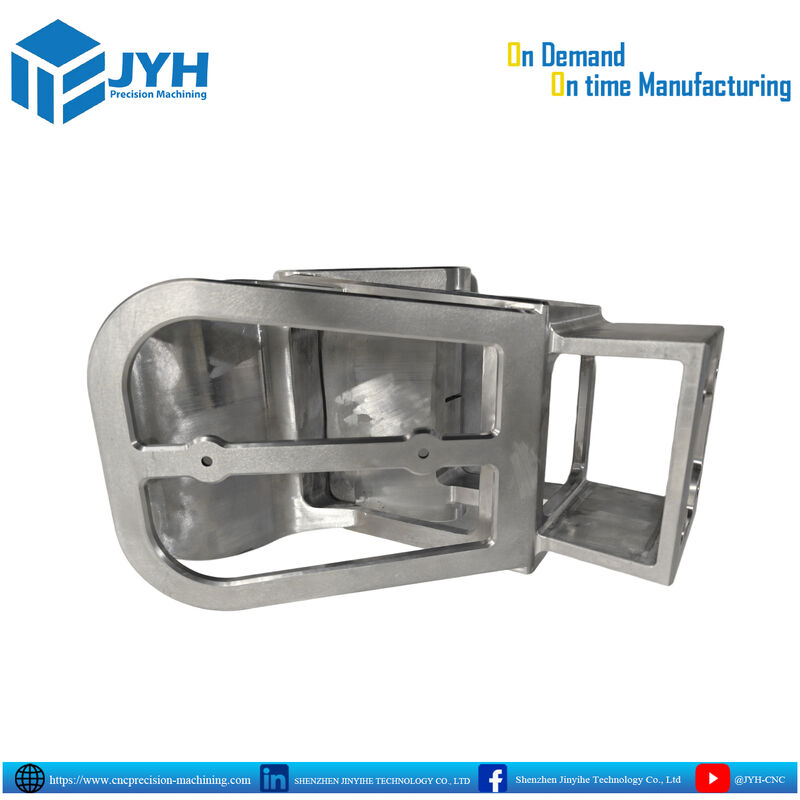

This advanced mechanical component is manufactured from EN AW-7075-T6, an aerospace-grade aluminum alloy renowned for its exceptional strength-to-weight ratio, fatigue resistance, and dimensional stability. Leveraging a combination of 5-Axis CNC Machining and Wire EDM Cutting, the part achieves extremely tight tolerances, intricate geometries, and sharp internal transitions that conventional machining methods cannot produce.

Whether used in UAV structures, robotic assemblies, defense systems, or precision industrial equipment, this component reflects JYH Precision Machining’s commitment to engineering excellence, process innovation, and reliable on-demand production.

Key Features & Technical Highlights

Material: EN AW-7075-T6

- Ultra-high strength aluminum alloy (comparable to some steels)

- Excellent machinability and corrosion resistance

- Ideal for load-bearing and lightweight structural components

Manufacturing Processes

|

Process

|

Purpose

|

Benefits

|

|

5-Axis CNC Machining

|

Multi-angle milling of complex geometry

|

Superior accuracy, reduced setup time, ability to machine deep cavities & compound curves

|

|

Wire EDM Cutting

|

Sharp internal edges, slotting, precision trimming

|

Zero deformation, ultra-tight tolerances, exceptional surface quality on fine features

|

Engineering Capabilities Demonstrated

1. Complex Geometry Machining

- Large cavity pockets with multi-plane surfaces

- Smooth internal wall transitions and optimized structural rigidity

- High precision across intersecting angles and internal channels

2. Thin-Wall & Lightweight Structures

- Consistent thin-wall machining without vibration or deformation

- Ideal for aerospace or UAV components where every gram matters

3. Superior Dimensional Accuracy

- Achieved through advanced 5-axis toolpath simulation

- Combined with EDM to refine ultra-precise internal contours

4. Surface Quality & Uniformity

- Clean, burr-free finish

- Controlled machining marks ensuring surface integrity

Why EN AW-7075-T6 for High-Performance Components?

|

Property

|

Benefit

|

|

High Tensile Strength (510–580 MPa)

|

Suitable for load-bearing applications

|

|

Good Fatigue Resistance

|

Long-term durability under dynamic loads

|

|

Excellent Strength-to-Weight Ratio

|

Ideal for aerospace and UAV structures

|

|

Good Machinability

|

Efficient, clean machining with close tolerance control

|

|

Stable Under Stress

|

Reliable performance in high-stress environments

|

Applications

This component is engineered to meet the demanding requirements of:

- Aerospace components & airframe assemblies

- UAV frames, gimbals, and payload housings

- Robotic arms, automation modules, and precision fixtures

- Motorsport and high-performance mechanical systems

- Defense and tactical device housings

- Prototype-to-production engineering solutions

Why Choose JYH Precision Machining?

On-Demand Manufacturing

Flexible production scheduling for prototype, low-volume, and mass production.

On-Time Delivery

Optimized workflows and real-time monitoring ensure consistent delivery timelines.

Engineering-Driven Quality

Our teams specialize in:

- Tolerance optimization

- Material behavior analysis

- Multi-step machining sequences

- Rapid iteration and technical support

Full-Service Manufacturing

CNC Milling | CNC Turning | 5-Axis Machining | EDM | Injection Molding | Sheet Metal

Finishing | Assembly | Inspection | Packing & Global Shipping

Product Summary Table

|

Specification

|

Details

|

|

Material

|

EN AW-7075-T6 Aluminum

|

|

Primary Process

|

5-Axis CNC Machining

|

|

Secondary Process

|

Wire EDM Cutting

|

|

Tolerance Capability

|

±0.005–0.01 mm (application-dependent)

|

|

Surface Finish

|

Machined aluminum finish

|

|

Application Sectors

|

Aerospace, UAV, Robotics, Industrial Automation

|

|

Key Strengths

|

Lightweight, high-strength, complex geometry precision

|

Professional Closing Statement

This EN AW-7075-T6 precision machined component embodies the highest standards of advanced manufacturing. From its deep cavities and thin-wall accuracy to EDM-refined contours, every feature is engineered for maximum performance and reliability.

At JYH Precision Machining, we transform complex engineering designs into high-precision, production-ready components—On Demand, On Time, Every Time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!