Product Overview

At JYH Precision Machining, we specialize in manufacturing high-precision aluminum die casting components combined with CNC secondary machining to achieve superior dimensional accuracy, surface finish, and functional reliability.

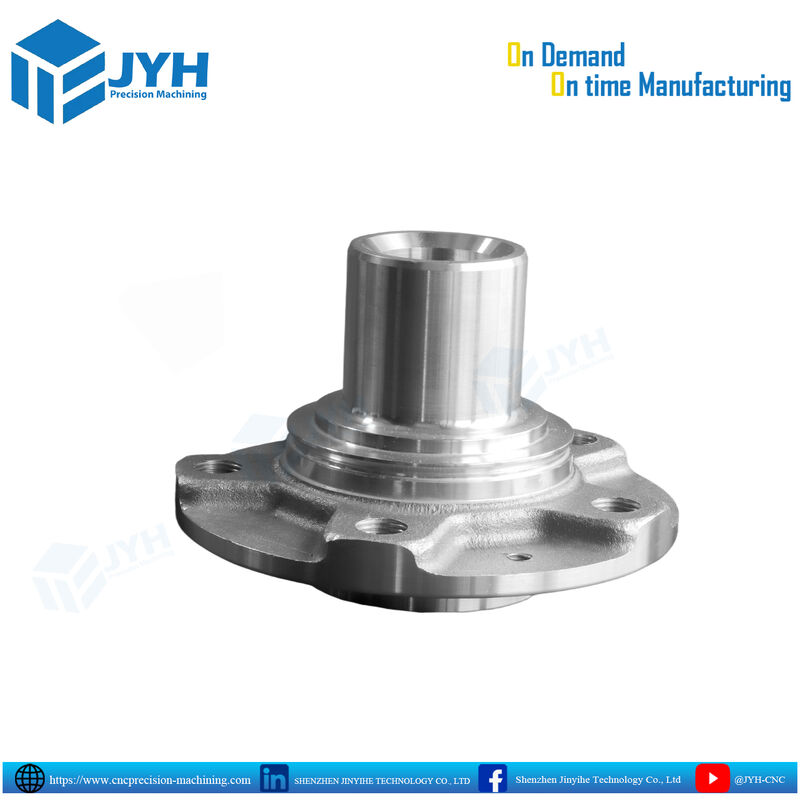

The product shown above is a precision die-cast aluminum hub/flange housing, widely used in automotive, industrial equipment, robotics, and electromechanical assemblies. This part demonstrates our capability to integrate die casting efficiency with CNC machining accuracy, delivering production-ready components that meet tight tolerances and demanding performance requirements.

With over 10 years of hands-on experience in precision manufacturing, our engineering team ensures every part is produced with strict quality control — from mold design to final inspection.

Manufacturing Process

This component is produced using a hybrid manufacturing approach:

- High-Pressure Aluminum Die Casting – for near-net shape, structural integrity, and cost efficiency

- CNC Precision Machining – for critical dimensions such as bore diameter, mounting faces, and threaded holes

- Deburring & Surface Preparation – to remove sharp edges and improve appearance

- Quality Inspection (CMM + Manual Gauges) – to ensure dimensional compliance

- Optional Surface Treatment – anodizing, powder coating, painting, or custom finishes

This process combination allows us to achieve both high-volume efficiency and precision-level accuracy.

Typical Specifications (Customizable)

|

Parameter

|

Capability

|

|

Material

|

Aluminum Alloy (ADC12, A380, A356, or custom)

|

|

Process

|

Die Casting + CNC Machining

|

|

Dimensional Tolerance

|

±0.01 mm achievable after CNC

|

|

Surface Roughness

|

Ra 0.8–3.2 μm

|

|

Part Weight Range

|

0.1 kg – 10 kg

|

|

Max Part Size

|

Up to 800 mm

|

|

Thread Types

|

Metric / UNC / UNF

|

|

Production Volume

|

Prototype to mass production

|

|

Lead Time

|

7–25 days (depending on quantity & complexity)

|

✅ All parameters can be customized according to your drawings or samples.

Key Features & Advantages

- High structural strength from pressure die casting

- Precision-machined critical interfaces

- Excellent repeatability for batch production

- Smooth surface finish suitable for decorative or functional coating

- Cost-effective for medium to high volumes

- Tight tolerance capability for assembly-critical parts

- Full in-house manufacturing: casting + machining + finishing

Applications

This type of die-cast hub component is commonly used in:

- Automotive wheel hubs & brackets

- Electric motor housings

- Robotics assemblies

- Industrial machinery

- UAV & drone structural parts

- Automation equipment

- Mechanical transmission systems

Die Casting + CNC vs CNC from Solid Billet

|

Item

|

Die Casting + CNC

|

CNC from Solid Block

|

|

Material Utilization

|

High

|

Lower

|

|

Cost for Volume

|

Lower

|

Higher

|

|

Internal Structure

|

Dense & uniform

|

Solid

|

|

Lead Time (Mass Production)

|

Faster

|

Slower

|

|

Surface Complexity

|

Excellent

|

Limited

|

|

Ideal Quantity

|

Medium–High volume

|

Prototype / Low volume

|

For complex geometries and production quantities, die casting with CNC finishing offers significant cost and efficiency advantages.

Quality Control

Every batch is inspected under our strict QC system:

- Incoming material verification

- First Article Inspection (FAI)

- In-process dimensional checks

- CMM measurement for critical tolerances

- Visual & surface inspection

- Final inspection before shipment

We follow ISO-based quality procedures to ensure consistency and reliability.

Optional Surface Treatments

- Anodizing

- Powder coating

- Painting

- Sandblasting

- Shot blasting

- Electroplating

- Custom finishes on request

Packaging & Logistics

- Individual protective packing

- Anti-scratch separation

- Custom foam or tray packaging

- Export-grade cartons or wooden cases

- Global shipping support (DHL / FedEx / UPS / Sea Freight)

Why Choose JYH Precision Machining?

- 10+ years manufacturing experience

- In-house CNC + die casting capability

- Strong engineering support

- Fast quotation & DFM feedback

- Competitive pricing

- Strict quality control

- One-stop solution: design → production → finishing → delivery

At JYH Precision Machining, we don’t just manufacture parts — we help optimize your product for performance, cost, and scalability.

Get a Quote Today

To receive a fast quotation, please send:

- 2D drawings / 3D files (STEP / IGES / STL)

- Material requirement

- Quantity

- Surface finish

- Tolerance requirements

Contact us anytime for technical support or pricing.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!