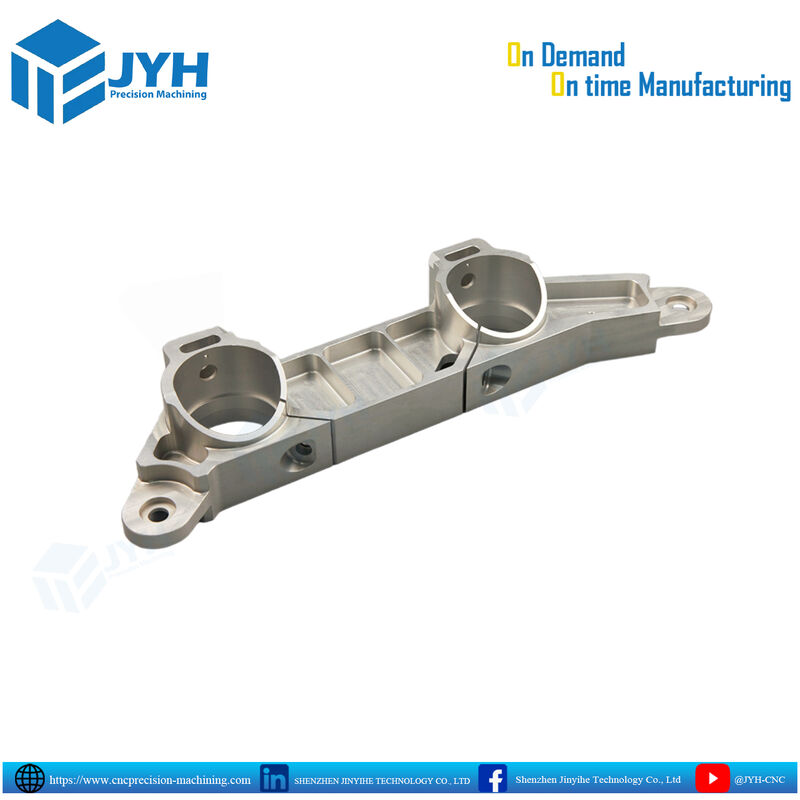

High-Precision CNC Machined Aluminum Structural Bracket for Industrial Applications

This CNC precision machined aluminum bracket is a high-strength, lightweight structural component manufactured for demanding mechanical, aerospace, UAV, robotics, and industrial applications. Produced using advanced multi-axis CNC milling, the part delivers exceptional dimensional accuracy, surface finish, and repeatability—ideal for both prototype and mass production requirements.

At JYH Precision Machining, we specialize in custom CNC machining services, providing OEM and ODM aluminum components tailored exactly to your drawings and performance needs.

Key Product Features

✔ Precision CNC Machining

· Manufactured using 3-axis and 5-axis CNC machining

· Tight tolerances up to ±0.01 mm

· Excellent concentricity and positional accuracy for cylindrical bores

✔ Lightweight & High Strength

· Optimized pocket design reduces weight without compromising strength

· Reinforced rib structure ensures rigidity under load

· Ideal for vibration-sensitive and dynamic assemblies

✔ Premium Aluminum Materials

· Aluminum 6061-T6 / 7075-T6 available

· High strength-to-weight ratio

· Excellent machinability and corrosion resistance

✔ Superior Surface Quality

· Smooth CNC-machined surfaces

· Burr-free edges and chamfered corners

· Ready for anodizing, coating, or further finishing

✔ Fully Customizable

· Dimensions, tolerances, and features per customer drawings

· Logo engraving and part marking available

· Prototype, small batch, and mass production supported

Applications of CNC Machined Aluminum Brackets

This custom CNC aluminum bracket is widely used in:

· UAV & Drone Structures

· Aerospace Mechanical Components

· Robotics & Automation Systems

· Automotive Performance Parts

· Industrial Machinery & Equipment

· Precision Bearing & Shaft Mounts

CNC Machining Technical Specifications

|

Specification

|

Details

|

|

Machining Process

|

CNC Milling (3-Axis / 5-Axis)

|

|

Material Options

|

Aluminum 6061-T6, 7075-T6

|

|

Tolerance

|

±0.01 mm (or per drawing)

|

|

Surface Finish

|

Machined, Bead Blasted, Anodized

|

|

Heat Treatment

|

T6 (optional)

|

|

Production Volume

|

Prototype to High-Volume

|

|

Inspection

|

CMM, Dimensional Report

|

|

Customization

|

Full OEM / ODM Support

|

Aluminum Material Comparison for CNC Machining

|

Property

|

Aluminum 6061-T6

|

Aluminum 7075-T6

|

|

Tensile Strength

|

~310 MPa

|

~570 MPa

|

|

Machinability

|

Excellent

|

Very Good

|

|

Corrosion Resistance

|

Very Good

|

Moderate

|

|

Weight

|

Lightweight

|

Lightweight

|

|

Cost

|

Economical

|

Higher

|

|

Typical Use

|

General CNC parts

|

Aerospace & UAV parts

|

Available Surface Treatments

· Clear / Color Anodizing

· Hard Anodizing

· Bead Blasting

· Powder Coating

· Passivation

Surface treatments improve corrosion resistance, wear resistance, and appearance, meeting both functional and aesthetic requirements.

Quality Control & Inspection

Every CNC machined aluminum part undergoes strict quality control:

· Material verification

· In-process inspection

· Final dimensional inspection

· Optional full inspection report & material certificate

This ensures consistent quality and reliable performance for every order.

Why Choose JYH Precision Machining?

· 10+ years of CNC machining experience

· Advanced CNC milling equipment

· Strong expertise in UAV & aerospace CNC parts

· Fast quotation and short lead times

· Competitive factory-direct pricing

· Professional engineering support

Custom CNC Machining Service

We accept:

· 2D drawings (PDF, DWG)

· 3D models (STEP, IGES, STL)

· Sample-based reverse engineering

Contact us today for a fast quote on your custom CNC machined aluminum parts.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!