Product Overview

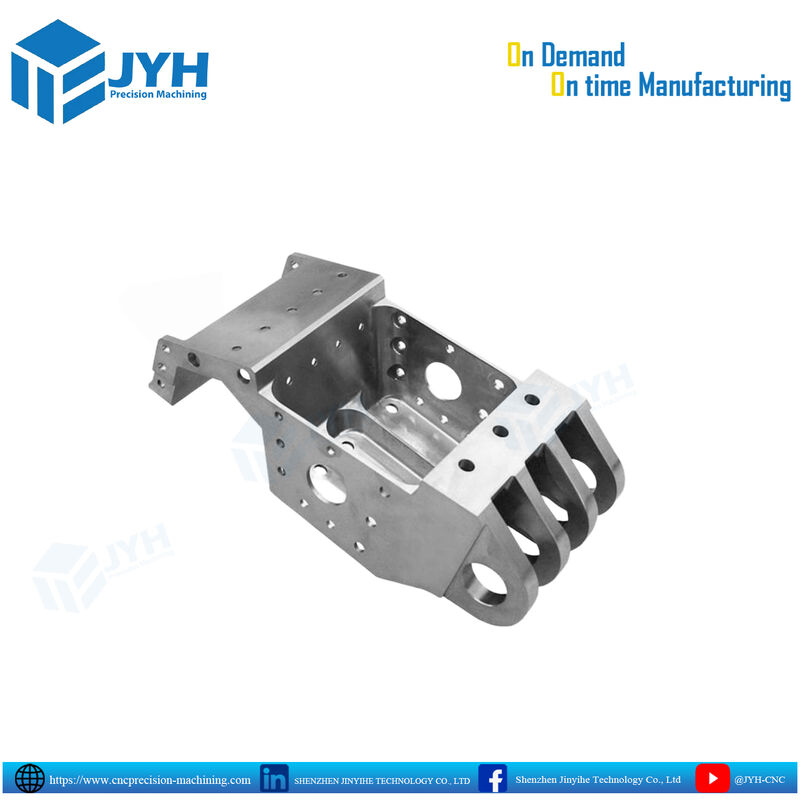

This CNC Machined Aluminum Mounting Bracket is a high-precision structural component designed for demanding mechanical, aerospace, robotics, and industrial automation applications. Manufactured using advanced multi-axis CNC machining, the part delivers excellent dimensional accuracy, mechanical strength, and repeatability, making it ideal for both prototype and production volumes.

The complex geometry, multiple mounting interfaces, and weight-optimized design indicate this component is engineered to support high load transmission, alignment accuracy, and vibration resistance, while maintaining a compact footprint.

Key Features & Advantages

· High-Precision CNC Machining

Manufactured on 3-axis / 4-axis / 5-axis CNC machining centers to ensure tight tolerances, excellent surface finish, and consistent quality.

· Lightweight Yet Rigid Structure

Optimized pocketing and internal cavities reduce weight without compromising structural integrity.

· Complex Multi-Face Machining

Multiple threaded holes, through holes, and contoured faces machined in a single setup sequence for superior positional accuracy.

· Excellent Load-Bearing Capability

Thick wall sections and reinforced mounting lugs provide strong resistance to bending and torsional loads.

· Assembly-Friendly Design

Precisely located mounting holes and alignment surfaces ensure easy integration into assemblies and reduce installation time.

Material Options

Although this sample part appears to be machined from aluminum, the design can be manufactured in multiple engineering materials depending on application requirements.

|

Material

|

Properties

|

Typical Applications

|

|

Aluminum 6061-T6

|

Lightweight, corrosion resistant, good machinability

|

Robotics, UAVs, fixtures

|

|

Aluminum 7075-T6

|

High strength, aerospace-grade

|

Aerospace, defense

|

|

Stainless Steel 304 / 316

|

High corrosion resistance, durability

|

Marine, medical

|

|

Steel (1045 / Alloy Steel)

|

High strength, cost-effective

|

Industrial machinery

|

|

Titanium (Grade 2 / Grade 5)

|

Extreme strength-to-weight ratio

|

Aerospace, motorsports

|

Manufacturing Capabilities

· CNC Milling (3-axis / 4-axis / 5-axis)

· CNC Turning (if combined features required)

· Tight tolerance control (±0.01 mm or better upon request)

· In-process and final quality inspection

· CMM measurement support

Surface Finish Options

|

Finish Type

|

Purpose

|

|

As-Machined

|

Functional prototypes, cost-effective

|

|

Anodizing (Clear / Black / Color)

|

Corrosion resistance, aesthetics

|

|

Hard Anodizing

|

Wear resistance, longer service life

|

|

Bead Blasting

|

Uniform matte appearance

|

|

Powder Coating

|

Enhanced protection and color options

|

|

PEO / Micro-Arc Oxidation (for Mg/Al)

|

High wear & thermal resistance

|

Typical Applications

· Robotics & Automation Systems

· UAV / Drone Structural Assemblies

· Aerospace Brackets & Housings

· Industrial Machinery Frames

· Motor Mounts & Actuator Supports

· Precision Fixtures & Jigs

Quality Assurance

Every component is produced under a strict quality control process:

· Incoming material verification

· In-process dimensional inspection

· Final inspection with CMM / gauges

· Surface finish and visual inspection

· Full traceability available upon request

Certifications such as ISO 9001 and material certificates can be provided if required.

Customization & OEM Support

· Fully customizable based on 2D drawings, 3D CAD files (STEP / IGES / STL)

· Prototyping to mass production support

· Design for Manufacturability (DFM) feedback

· Low-volume and high-mix production available

Why Choose JYH Precision Machining?

· Over 10 years of CNC machining experience

· Strong expertise in complex structural parts

· Competitive pricing with stable lead times

· One-stop solution: machining + finishing + assembly

· Trusted by global clients in aerospace, robotics, and industrial sectors

Request a Quote

Send us your drawings and technical requirements today. Our engineering team will provide fast feedback, competitive pricing, and reliable manufacturing solutions tailored to your project.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!